How Automated Data Reporting Supports Companies in Achieving Carbon Certifications

Sentra.world is a transformative carbon emission management solution designed to help industries reduce their carbon footprint and transition to a sustainable future. By integrating advanced technologies and user-centric design, it simplifies the path to achieving net-zero goals.

Introduction

It all started with a visit to Bangalore, where we met Harsh Chaudhari, an ex-Jr McKinsey partner, and Vikas Upadhyay. Both shared a clear and compelling vision: to create a one-stop software solution that would help steel and aluminium manufacturers around the world measure, monitor, and reduce their carbon footprint. This vision gave birth to Sentra.world.

Sentra.world is a forward-thinking company with a strong commitment to protecting the environment. Their mission goes beyond simply building a product, they aim to inspire a global movement towards a greener, cleaner, and more sustainable world for future generations.

Their innovative platform operates across India, the Middle East, and Southeast Asia. It combines smart artificial intelligence with blockchain technology to provide manufacturers with transparent, accurate, and easy-to-use tools to understand and reduce their carbon emissions.

When Sentra.world approached us, they had a bold ambition: to develop a transformative software solution that could empower manufacturers to embrace sustainability while simplifying the complexities of carbon emissions management.

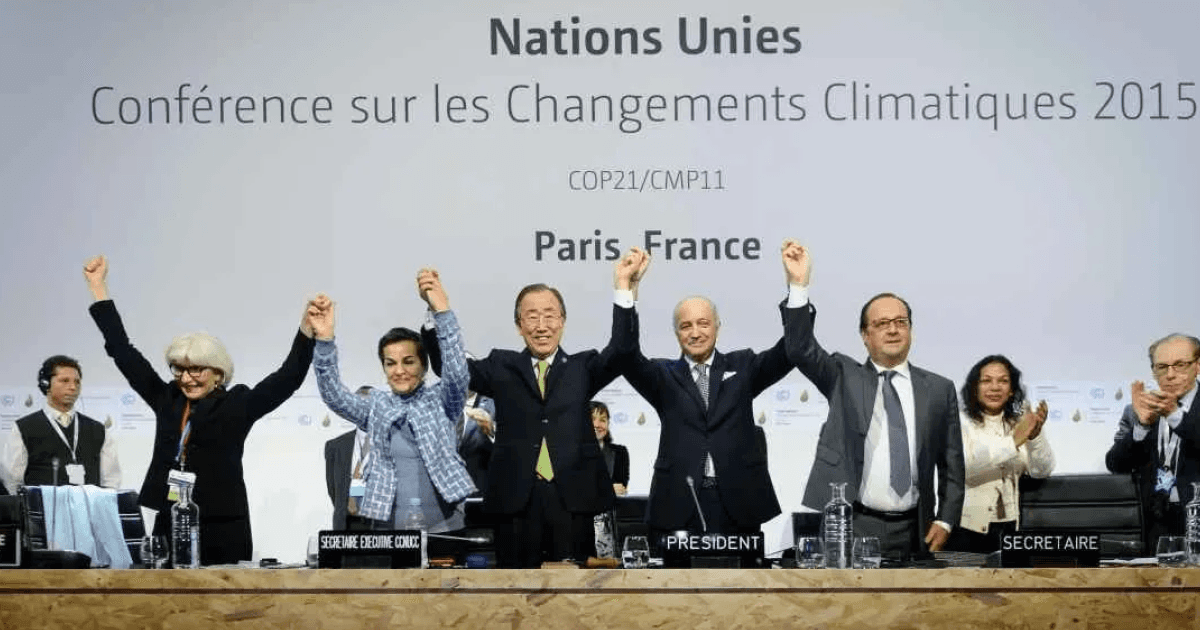

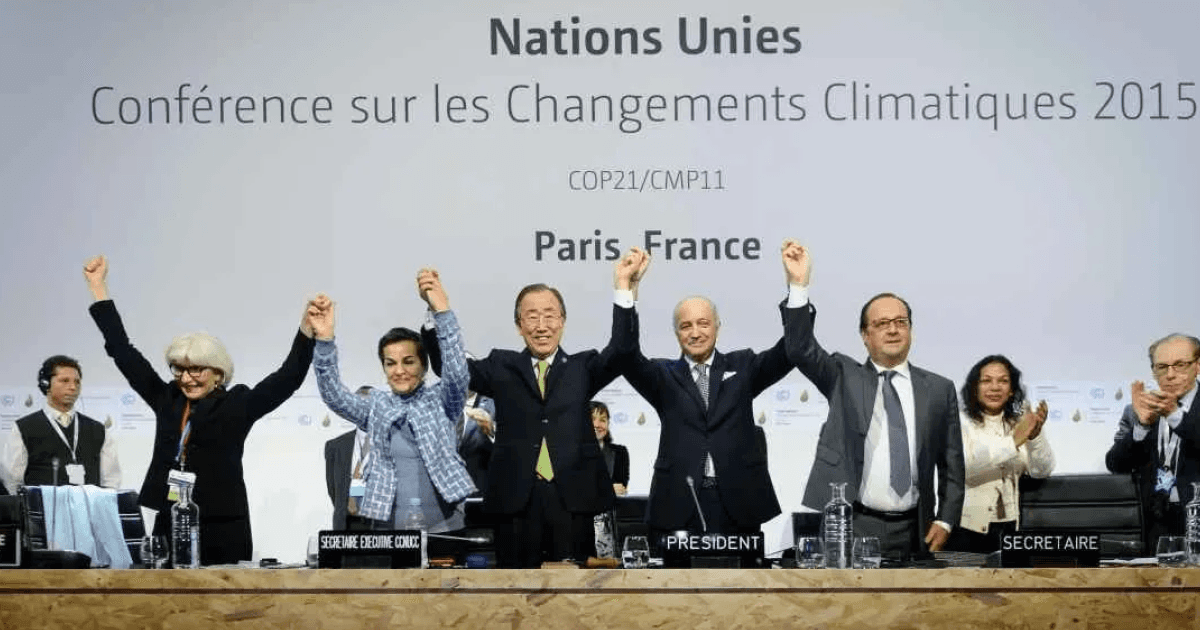

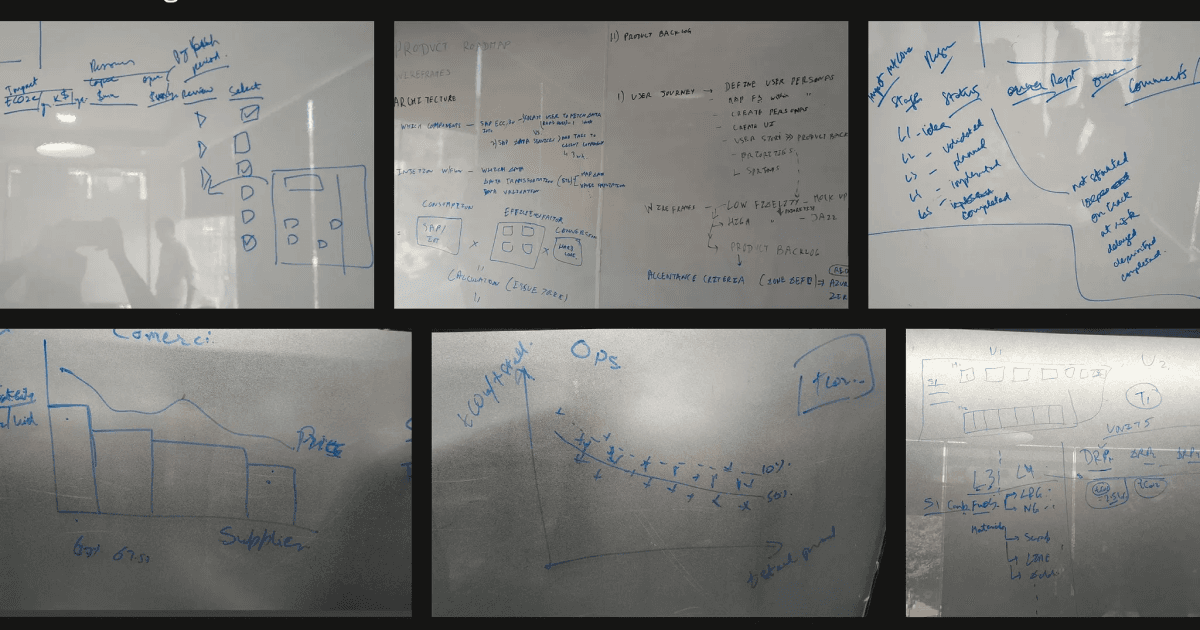

To do this, we organised and participated in a series of workshops with industry experts, environmentalists, and regulatory bodies.

The Problem

Manufacturing industries today face unprecedented challenges when it comes to reducing their environmental impact. The urgency to lower carbon emissions is stronger than ever, driven by increasing environmental concerns, tighter regulations, and growing expectations from consumers and stakeholders.

Some of the key challenges they face include:

Fragmented and inconsistent data: Manufacturers collect data from multiple sites, machines, and processes. However, this data is often scattered across different formats and systems, which makes it difficult to consolidate and analyze. Without a unified source, calculating accurate emissions becomes unreliable and prone to errors.

Manual and time-consuming processes: Traditional carbon reporting involves tedious manual data entry and complex spreadsheet calculations. This not only consumes valuable time but also increases the risk of human errors that can distort results or lead to compliance issues.

Lack of actionable insights: Even when emissions data is available, it is often presented in a way that is hard to understand or interpret. Manufacturers struggle to identify which parts of their operations contribute the most to their carbon footprint and what specific steps they should take to reduce it.

Difficulty in tracking progress and compliance: Setting carbon reduction goals is only part of the challenge. Companies also need to monitor their progress continuously and generate reports that satisfy regulatory requirements. Doing this manually or with disconnected tools is inefficient and makes it hard to stay on track.

These challenges created a significant barrier for Sentra.world’s clients. They needed a solution that could not only simplify data collection and reporting but also provide clear, real-time insights to guide decision-making. Without this, achieving meaningful carbon reductions and regulatory compliance would remain an uphill battle.

The Solution

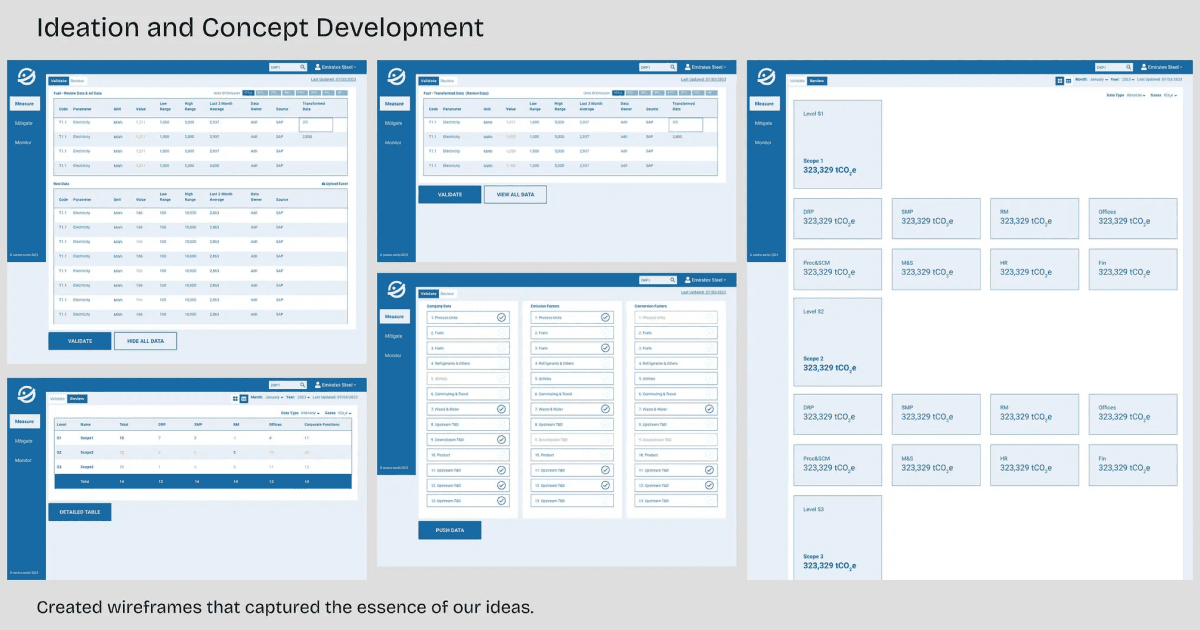

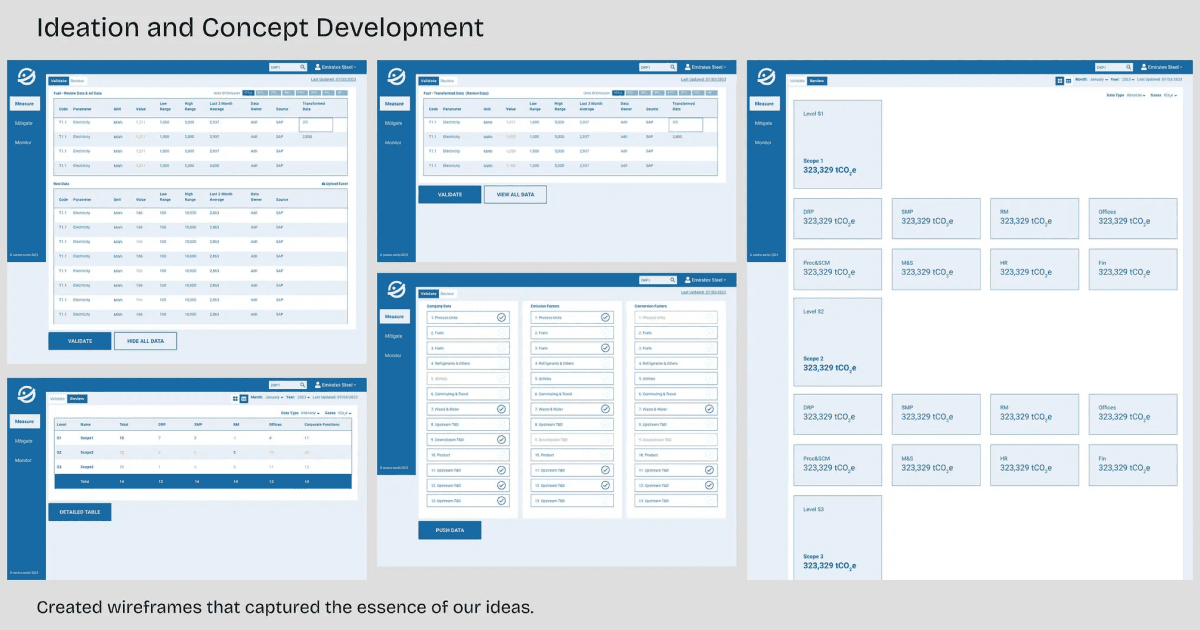

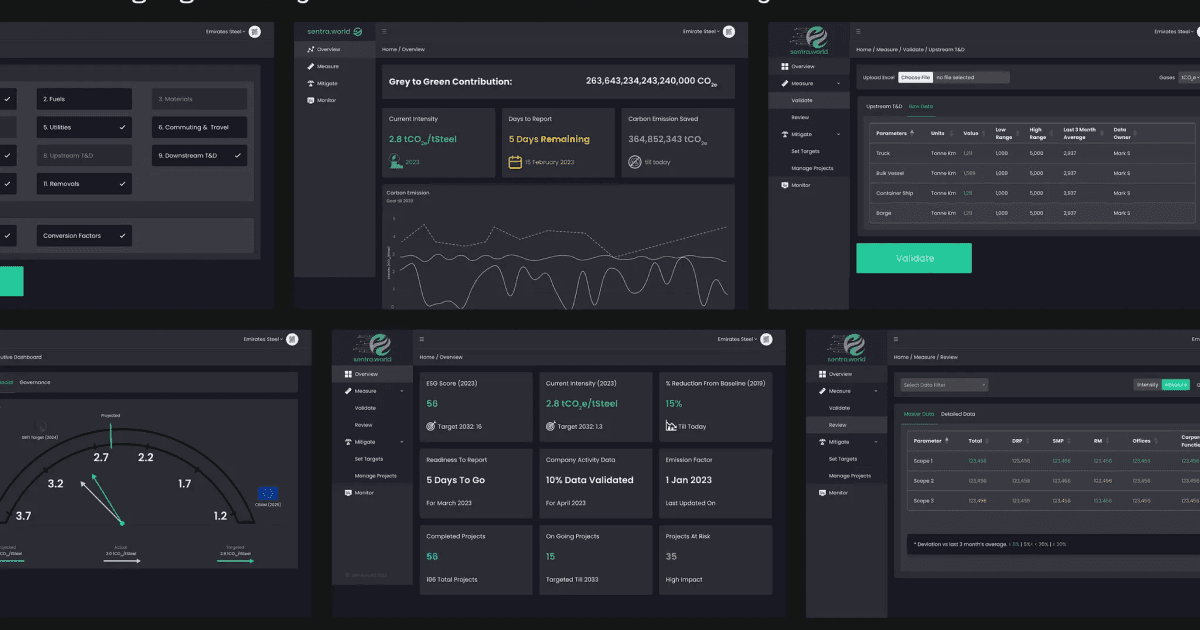

Our team partnered closely with Harsh, Vikas, and the Sentra.world leadership to design and develop a cloud-based software platform tailored specifically for the manufacturing industry. The goal was to create a one-stop solution that would simplify carbon tracking, make data easy to understand, and help users take action with confidence.

The solution focused on several core components:

Data mapping and standardization: We created processes to gather data from multiple sources and convert it into a consistent, standardized format. This ensured that the platform could perform accurate emissions calculations across different manufacturing sites, regardless of the original data structure or origin.

Real-time calculation engine: A powerful engine was developed to process incoming data continuously and calculate carbon footprints instantly. This real-time capability was crucial because it allowed users to see up-to-date information about their emissions, rather than waiting for periodic reports.

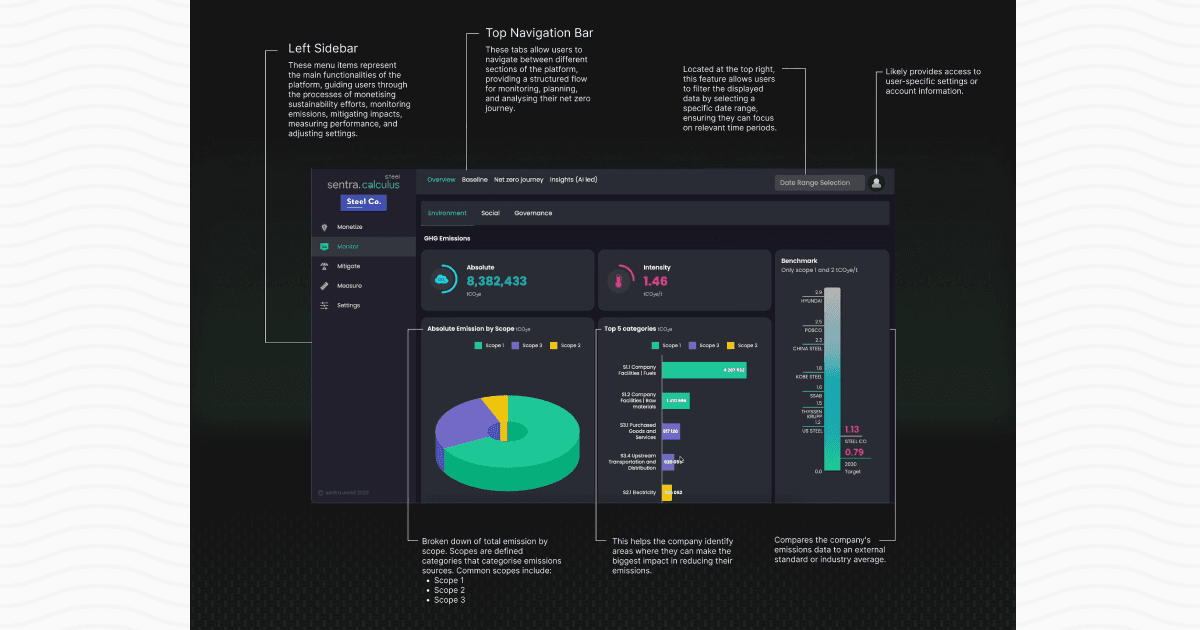

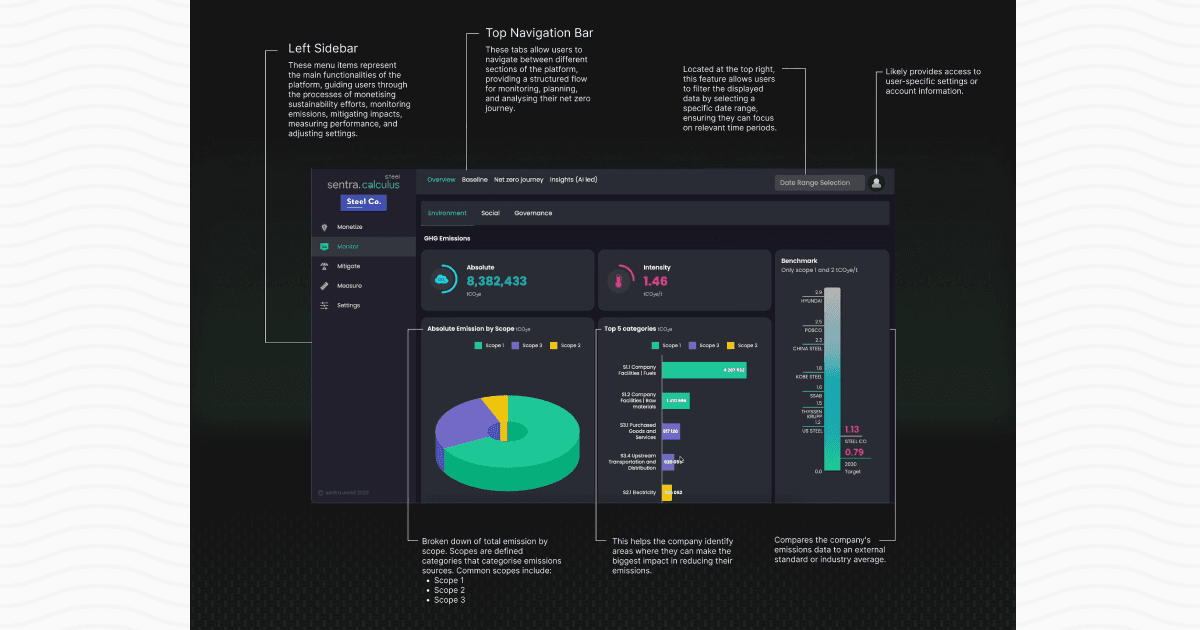

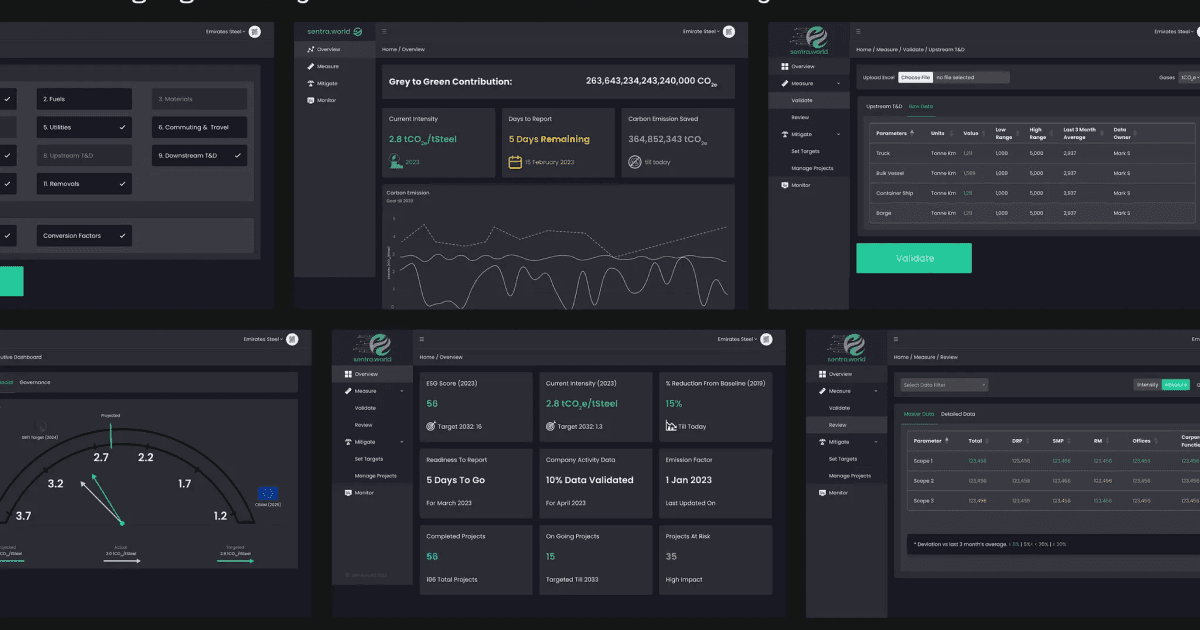

User-friendly dashboards and reports: The platform was designed with simplicity in mind. Instead of overwhelming users with technical jargon or complicated graphs, we focused on clear visuals and intuitive navigation. This made it easy for various teams — from operators to sustainability managers — to understand emissions data and track progress.

Goal setting and project tracking tools: Manufacturers could set specific carbon reduction targets within the platform and receive tailored recommendations for decarbonization projects. The system also tracked the impact of these projects over time, helping clients measure real results and adjust strategies accordingly.

We followed a well-structured delivery process, starting with understanding the client’s needs, mapping data, building the calculation engine, and designing the user interface. Rigorous testing ensured the platform was robust and easy to use. Post-launch, we offered ongoing support, training, and documentation to help Sentra.world and its clients make the most of the software.

By combining smart technology with a user-centric design, we helped Sentra.world create a tool that transforms how manufacturers approach carbon emissions management.

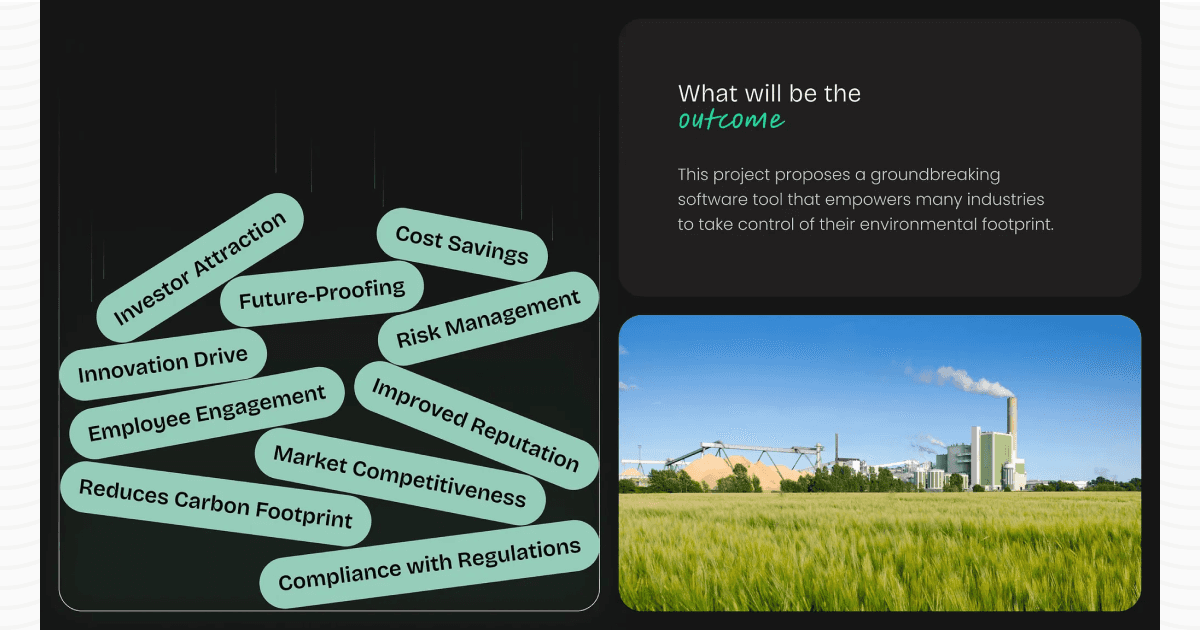

The Impact

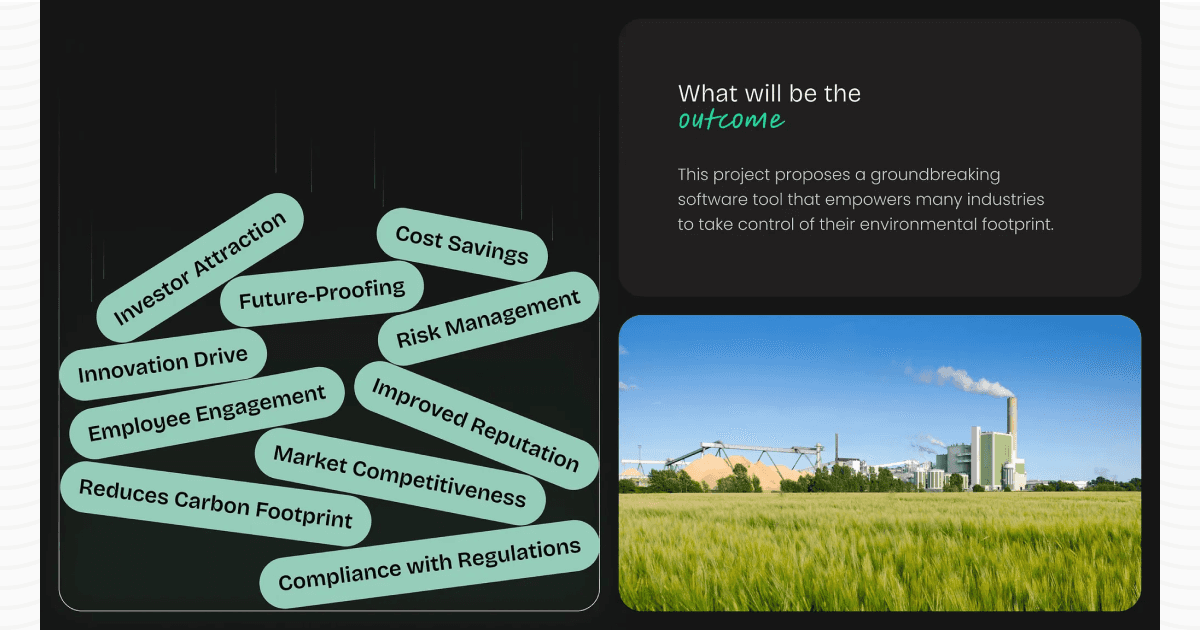

The results of this collaboration have been significant and far-reaching. Since going live, Sentra.world’s platform has transformed how manufacturers measure and manage their carbon emissions.

Real-time emissions tracking: Manufacturers can now monitor their carbon footprint continuously across multiple facilities. This real-time data visibility allows them to react quickly to changes, identify emission spikes as they occur, and make informed decisions to reduce their impact.

Dramatic time savings: Automation and data standardization eliminated the need for most manual data entry and calculations. Clients reported saving between 70 to 80 percent of the time previously spent on these tasks, freeing teams to focus on strategic sustainability initiatives instead.

Clear insights for targeted action: The platform’s dashboards highlight key emission hotspots and areas where reduction efforts will have the greatest impact. This clarity helps companies prioritize projects and allocate resources more effectively to drive meaningful carbon cuts.

Simplified compliance and reporting: Automated report generation reduced the complexity and effort involved in meeting regulatory requirements. Manufacturers can now produce accurate, audit-ready reports quickly and consistently.

Improved collaboration and accountability: With accessible data and shared dashboards, teams across different sites and departments are better aligned on sustainability goals. The platform fosters a culture of accountability and continuous improvement.

The transformation brought by Sentra.world’s platform has not only improved sustainability performance but also boosted operational efficiency and team productivity. By turning data into clear, actionable insights, the solution empowers manufacturers to accelerate their journey to a Net Zero future with confidence.

Sentra.world plans to continue expanding the platform’s capabilities and reach. Their ultimate goal remains inspiring and enabling a global movement toward a cleaner, more sustainable planet.

Visuals

We are a family of Promactians

We are an excellence-driven company passionate about technology where people love what they do.

Get opportunities to co-create, connect and celebrate!

Vadodara

Headquarter

B-301, Monalisa Business Center, Manjalpur, Vadodara, Gujarat, India - 390011

+91 (932)-703-1275

Ahmedabad

West Gate, B-1802, Besides YMCA Club Road, SG Highway, Ahmedabad, Gujarat, India - 380015

Pune

46 Downtown, 805+806, Pashan-Sus Link Road, Near Audi Showroom, Baner, Pune, Maharashtra, India - 411045.

USA

4056, 1207 Delaware Ave, Wilmington, DE, United States America, US, 19806

+1 (765)-305-4030

Copyright ⓒ Promact Infotech Pvt. Ltd. All Rights Reserved

We are a family of Promactians

We are an excellence-driven company passionate about technology where people love what they do.

Get opportunities to co-create, connect and celebrate!

Vadodara

Headquarter

B-301, Monalisa Business Center, Manjalpur, Vadodara, Gujarat, India - 390011

+91 (932)-703-1275

Ahmedabad

West Gate, B-1802, Besides YMCA Club Road, SG Highway, Ahmedabad, Gujarat, India - 380015

Pune

46 Downtown, 805+806, Pashan-Sus Link Road, Near Audi Showroom, Baner, Pune, Maharashtra, India - 411045.

USA

4056, 1207 Delaware Ave, Wilmington, DE, United States America, US, 19806

+1 (765)-305-4030

Copyright ⓒ Promact Infotech Pvt. Ltd. All Rights Reserved

We are a family of Promactians

We are an excellence-driven company passionate about technology where people love what they do.

Get opportunities to co-create, connect and celebrate!

Vadodara

Headquarter

B-301, Monalisa Business Center, Manjalpur, Vadodara, Gujarat, India - 390011

+91 (932)-703-1275

Ahmedabad

West Gate, B-1802, Besides YMCA Club Road, SG Highway, Ahmedabad, Gujarat, India - 380015

Pune

46 Downtown, 805+806, Pashan-Sus Link Road, Near Audi Showroom, Baner, Pune, Maharashtra, India - 411045.

USA

4056, 1207 Delaware Ave, Wilmington, DE, United States America, US, 19806

+1 (765)-305-4030

Copyright ⓒ Promact Infotech Pvt. Ltd. All Rights Reserved